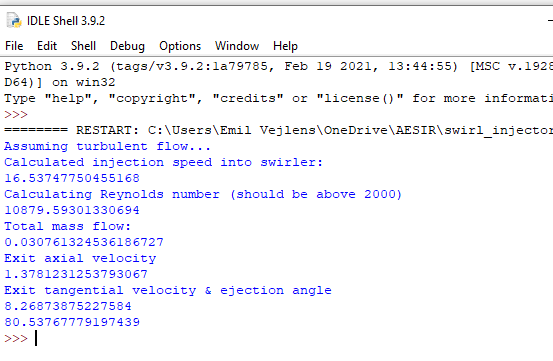

Recently been trying to figure out how swirl injectors for ethanol would work. This is a part of the rocket engine we’re building in one of the student organizations.

I’ve done some initial guesstimates using my knowledge from fluid mechanics, a course I recently finished. Swirlers work by injecting the fuel (or oxidizer) into a cylinder tangentially, this creates the rotating motion (the swirl). One end of the cylinder is left open towards the combustion chamber, and when the “swirling flow” reaches this it will expand out in a cone, due to the rotational speed.

My guesstimates is just quickly put together from my understanding of pipe flows. Using this I can calculate the mass flow and exit speed of the fluid into the swirling chamber (the cylinder), this is usually just a hole drilled in the wall of the cylinder, so I can approximate this as a very small pipe. Calculating the speed at which the fluid moves down the cylinder (and therefore exits the cylinder) is not really possible using the current models I know. I can make an estimate just using conservation of massflow, but this assumes the fluid fills up the entire swirl chamber, which I’m not sure it does.

TLDR is that I can give an extremely rough estimate for mass flow (which is important for our fuel mixture) and the exit cone angle of the injector. But since a lot of the assumptions I use for this doesn’t actually apply for the particular problem, the results (especially the angle) will be way of reality. Luckily we have another guy looking into the more advanced models to actually do this properly.

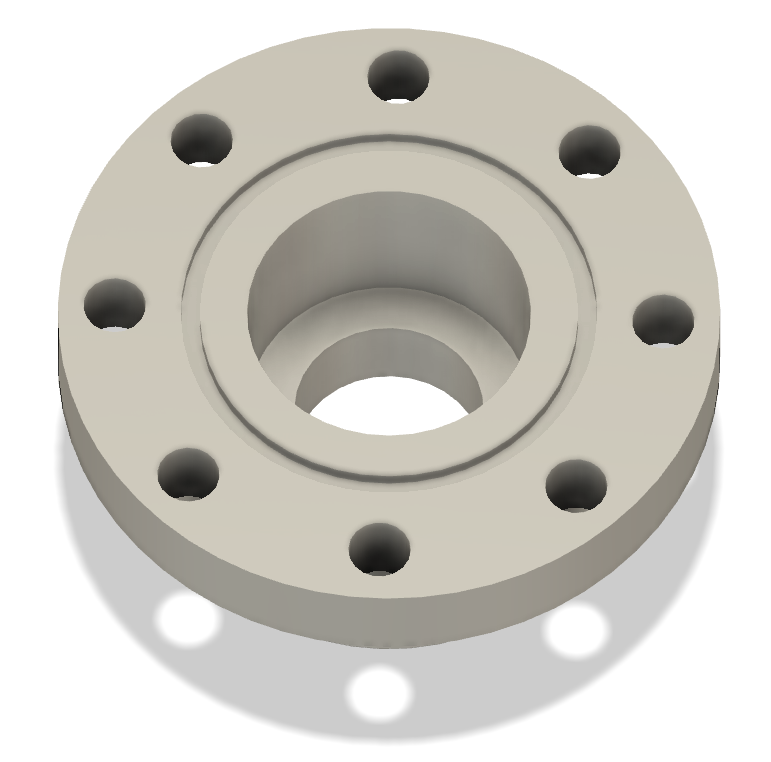

Once we have enough understanding to at least manufacture a prototype, we’ll have to test it and see if our predictions are right. This is actually my main thing right now. Designing an adapter to attach the swirler to a testrig (we already have a testrig for another project). Most of it is just spending a lot of hours in doing CAD, but we will hopefully start manufacturing parts soon. This also means I’ll get to learn all the fancy tools in the workshop during the next few weeks.